Precise measurements – efficient and clean driving

An innovative and high-precision fuel consumption measurement system is about to be launched

The shipping industry is facing increasingly stringent regulations to reduce emissions. As early as this year, fuel consumption measurement will be given high priority in determining the EEDI and EIV indices as part of the MRV Regulation. As far as nitrogen oxides, sulphur and particulates are concerned, the international specifications of the MARPOL agreement have applied since 2016. The industry must expect further tightening of emission limits and the expansion of special emission areas.

Currently available expert systems for engine optimisation and for the online determination of pollutant emissions require precise information with a high temporal resolution on current fuel consumption. The same applies to the assistance systems of various manufacturers for drive optimisation which can make the operation of ships much more efficient. This can only be achieved with standardised concepts. The current non-standardised integration of measuring devices (which are certainly good and suitable) somewhere in the engine booster system means that inaccuracies in the measurement result are pretty high due to environmental influences. This makes it almost impossible to provide truly comparable data on fuel consumption. It therefore seems questionable whether the use of existing and certainly very worthwhile expert and assistance systems to minimise pollutant emissions are in fact effective in their current form and thus able to help minimise consumption.

In conjunction with the AVL EPOS™ expert system on the other hand, improvements to fuel consumption of up to 6g/kW*h can be achieved through enhancing the synchronisation of the cylinders by varying the injection quantities, for example. This can be displayed online. The integrated NOx module, which already meets the requirements of IMO MARPOL Annex VI, Resolution MEPC 103(49) and the NOx Technical Code, can be used for online determination and display of NOx, SOx and CO2 by tuning the engine to NOx best values or legally permitted values to immediately identify further savings potentials. Similar savings potentials can be achieved through the efficient use of assistance systems for propeller and rudder adjustment as well as for route optimisation.

This means that with a combination of powerful expert and assistance systems and consumption measurement systems that provide an accurate and precise representation of the current fuel consumption online, shipping companies can optimise the efficiency of their ships and save many tons of fuel that way. The condition monitoring function of the AVL EPOS™, for example, provides reliable information on the maintenance status of the machine. This provides the engine mechanic on duty and the ship management with immediate and reliable feedback on engine performance. The system provides reliable and comparable results for all ships in a fleet.

Cross-innovation as solution strategy

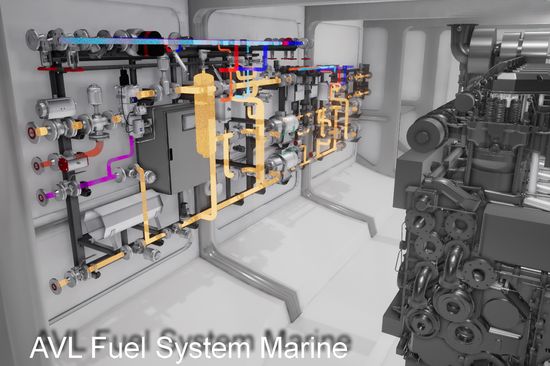

In the automotive industry, standardised, high-precision measuring systems to determine fuel consumption have been used for years. This is not the case in shipping. The adoption of tried-and-tested measurement techniques from the automotive industry in conjunction with the use of innovative expert and assistance systems would also make the operation of ships more efficient. This also applies to compliance with pollutant emissions. In combination with other high-resolution measurement methods, which measure additional operating data such as speed, cylinder pressure and emission parameters, the engine control system can be adjusted to increase engine efficiency. This would be useful when different fuels are used, for example. There is still a lot of potential for innovation here. Since such innovations are already used in the automotive industry and could thus also be implemented relatively inexpensively in shipping. The consumption measurement technology required for this calls for high information density of measured values, careful consideration of environmental influences to minimise measurement errors and it is a necessary and required component of AVL measurement systems in the test field of engines and vehicles in the automotive industry. The system architecture resulting from these requirements, which requires an integrated consideration of measurement and booster function to supply the engine with fuel, has been consistently transferred to the ship's engine.

The Graz-based AVL List GmbH, the world's largest independent company for the development of simulation and testing technology for drive systems and combustion engines, and the engineering firm HAWE from Gifhorn have been pushing ahead with the development of this fuel consumption measurement system optimised to deliver accurate and precise measurements since mid-2017.

Via the Maritime Cluster Northern Germany (MCN) contact was established with a medium-sized shipping company, the MCN member company Reederei Rass. This company is prepared to take the new AVL measurement system in conjunction with the AVL EPOS™ expert system on board one of its ships in order to confirm the predicted improvement in ship efficiency. Both parties benefit from this win-win situation: The shipping company gains first-hand experience of the new technology and is the first company to profitably deploy it. AVL List GmbH and the engineering firm HAWE on their part benefit from access to valuable real-life operating data, which they can use to further enhance the system. Marine Technik Manfred Schmidt GmbH from Ganderkesee will produce the prototype. The contact to the consortium was also established via the MCN.

Currently, all parties involved are working at full speed to bring the new AVL fuel consumption measurement technology together with the AVL EPOS™ expert system on board as quickly as possible in order to take the first step towards establishing more precise measurement systems to improve efficiency in shipping. The entire system will initially be put into operation on the engine test benches of the Department of Mechanical Engineering and Marine Technology at the University of Rostock, before being installed on the HOHEBANK vessel of Reederei Rass. The certification agency Bureau Veritas will provide specialist support throughout the implementation of the project.

Innovation through cooperation

The example shows that the promotion of meaningful business cooperations can generate real added value in the long term - with or without public funding. Taking a cross-industry perspective creates true synergy effects for the companies involved: The participating shipping companies enhance the efficiency of their ships and the companies involved open up new markets.

At the SMM 2018 it was possible to experience the system for the first time using virtual reality glasses, and at the minister and senator reception at the MCN stand it was given a high-profile introduction by IB-HAWE's Manfred Werner. The MCN has been supporting the project from the very beginning; in April 2018, for example, a workshop on the topic of "Precise fuel consumption measurement on board as a starting point for cross-industry innovation?" was jointly organised by the MCN with the MCN member IB- HAWE together with Braunschweig University and AVL List GmbH / Graz – the workshop results were incorporated into the development of the system.